Company

Company

Koremplast is a steady productive reality. The team has more than ten years of experience in the Polyethylene Compound production and an in-depth knowledge of the Plastic Materials market. Koremplast is present with its products and contacts in Europe, and in those countries bordering the Mediterranean sea, such as North Africa and Turkey, as well as in Italy. Koremplast has its own Technical/Productive and Laboratory/Quality Know-How, gained through collaborating with leading technology providers in the industry.

Mission

Mission

Koremplast has the prerogative of the Optimal Management of Sources. For this reason, it is committed in meeting the needs and requirements of its clients by supplying them high quality materials, with its highly skilled team and with its investments in new technology. Koremplast attaches great value to its human resources directing its efforts towards creating safer and more comfortable working places and improving the efficiency and productivity of the working environment.

Manufacturing

Manufacturing

Koremplast pays careful attention to the technical / productive aspect by choosing the Latest Technology of the plastic materials sector. Koremplast is equipped with: -high production capacity extruder -packaging plant

Products

Products

Koremplast produces high-medium and low density Polyethylene compounds, useful for the non-pressure PIPES production, smooth or corrugated of any diameter (cable duct, drainage, sewerage, irrigation) and for packaging – drums and bottles production. All the compounds are analyzed and controlled during the entire production process and subjected to continuous laboratory tests (M.F.I. - DENSITY - D.S.C. - O.I.T. - Carbon Black - Water Content); this is how we ensure steady and high quality. Koremplast is able to provide materials with specific technical features depending on clients special needs, upon request.

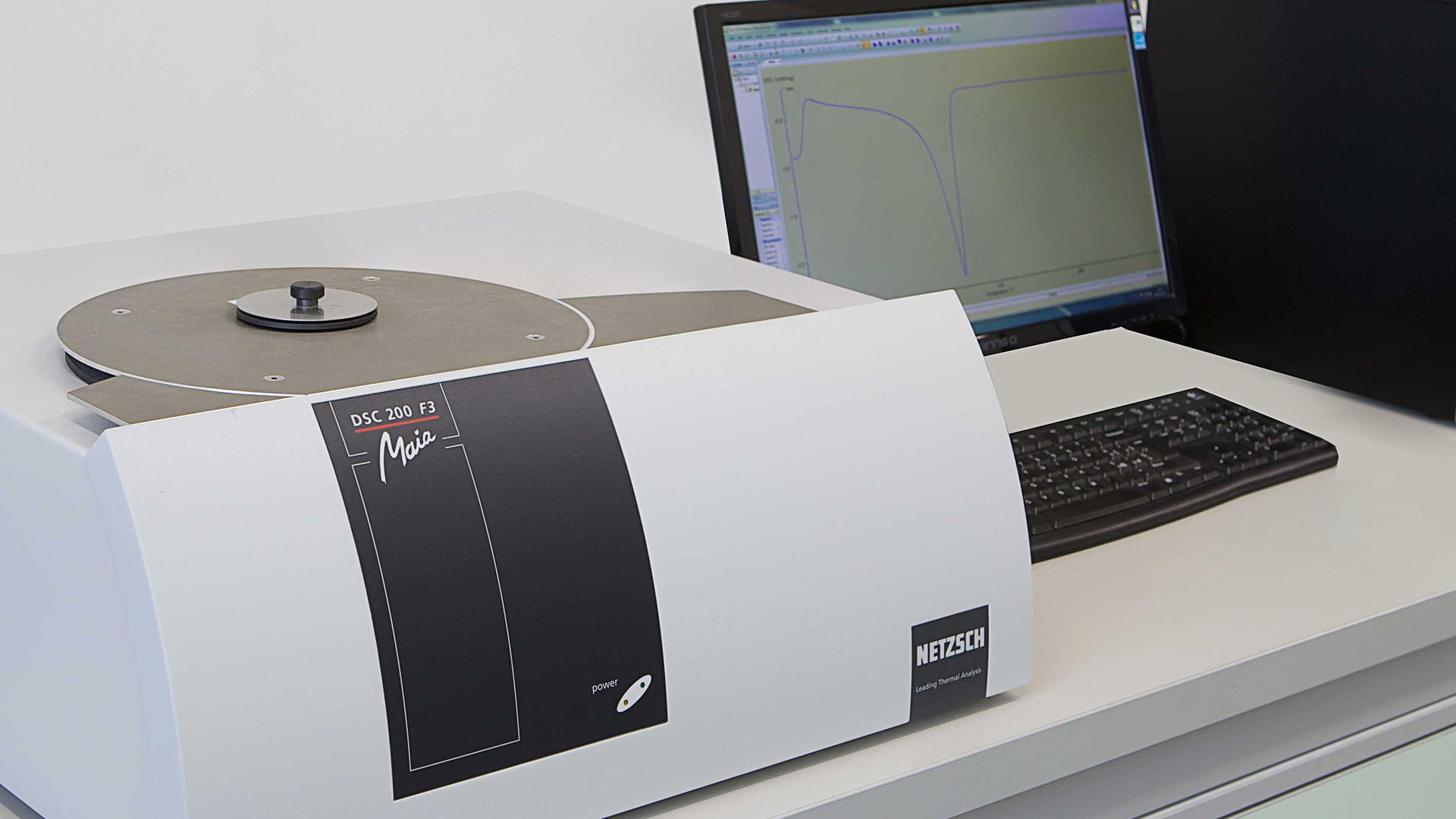

Lab/Quality/Certifications

Lab/Quality/Certifications

Counting on latest technology equipment Koremplast tests the incoming materials on arrival, during the production process and the finished product, in its own laboratory, in order to grant to customers the absolute quality of its compounds. Tests: - M.F.I. (g/10 min) - Density (g/cm3) - DSC (T) - OIT(min) - Carbon Black (%) - TGA (%) - Dynamometer - Durometer - IZOD (Kj/m2)